BCPCorporate Profile

BCP(Business Continuity Plan)

NTT LOGISICO has developed various business continuity plans (BCP) as a member of a communication infrastructure provider, the NTT Group.

NTT LOGISCO is equipped with a logistics center that exceeds quake resistance standards, a private power generation facility and fuel stockpile and also provides communication infrastructures including the backing up of logistics information systems.

We take a wide range of business continuity measures as a member of the NTT Group.

We would like to further enhance disaster prevention measures, leveraging lessons learned from what happened in the Great East Japan Earthquake and past disasters, and improve our response capability to ensure business continuity as a logistic company resilient to disasters.

Backup system in the event of disaster

- Prior registration of emergency vehicles

- Establishment of an emergency contact system including the use of satellite-based mobile phones

- Development of mutual backup between sites

- Prompt working availability checkup using a safety confirmation system

Quake resistance warehouse

(Kanagawa Logistics Center)

(Chiba Logistics Center)

Securing of power source using private power generation facility

Logistics centers have a power source securing measures for emergency situations such as solar power generation and private power generation systems

System data backup

Each logistics center has installed a UPS (uninterruptible power-supply system) to prevent logistic services from being interrupted even during power outages

Cloud logistics information system run by a robust datacenter is effective in ensuring data security from a disaster prevention perspective.

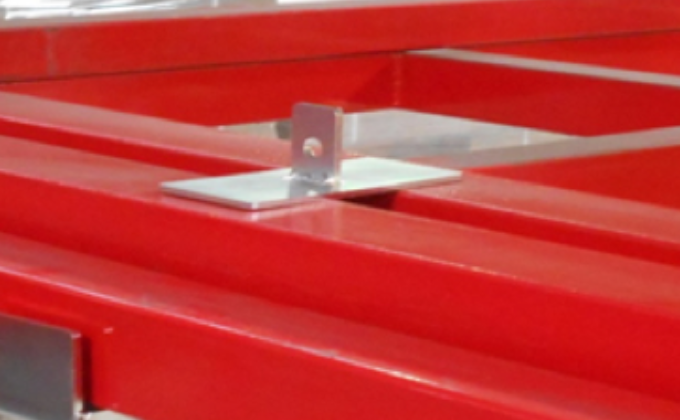

Quake resistance measures for storage equipments

In order to protect the goods of shippers, the floor of storage shelves is fixed by anchor bolts and shelves are connected to each other. In addition, NTT LOGISCO has developed rack unit connection fittings for the purpose of improving the stability of multi-stage Nestenor as part of anti-earthquake measures in warehouses, which are used by some customers for logistics.

(Patent No. 6155350 / design registration large 1559640)

Crisis management drill

NTT LOGISCO conducts crisis management drills on a regular basis in co-operation with cargo owner companies to prevent logistics operations from being interrupted in the case of disaster. The drill includes information communication in disasters, recovery of facilities and business continuity response.

- Initial response which covers from the disaster occurrence to the setting up of disaster response headquarters

-

Checking of disaster status

- Employees’ safety (email and call distribution to mobile and land phones for safety confirmation and management of reception status using a safety confirmation system)

- Presence of injured persons and first aid status

- Train service status and presence of people who have difficulty getting home from work

- Damage conditions of warehouse buildings, products in storage, equipments in warehouses, and information systems

- Road and traffic conditions including traffic restrictions and the service status of the shipping company

- Operation check for satellite-based mobile phones

-

Status report to customers based on the business continuity response and emergency contact system

- Emergency shipping and delivery vehicle arrangements upon customers request

- Arrangement of additional supportive staff for disaster recovery

- Checking the start of power generators and power supply at logistics center

- Checking the procedures for power source recovery for information systems